Technology

Ball Wave Inc.

- JP

- EN

Introduction to base technology

Ball SAW sensor

Solving global problems with a spherical sensor.

Features of the ball SAW sensor

The ball SAW sensor, which is the base technology of Ball Wave, is an innovative chemical sensing technology that delivers small size, high speed, and high sensitivity.

Diameter 1 mm

Small size

Small size due to the use of a special class of ultrasonic waves called surface acoustic waves (SAWs) confined near the surface of a sphere

Thin sensitive film

High speed

Since the circulating SAW passes across the sensitive film many times, a sufficient response to the trace gas molecules can be obtained even with a very thin sensitive film, which helps achieve the high speed response due to short diffusion time of the trace gas molecules within the thin film.

Long-distance propagation

High sensitivity (x100)

Although the change in the physical properties of the SAW by the adsorbed gas on the sensitive film is very small during each round-trip around the spherical sensor, the change is amplified and high sensitivity is achieved because the SAW travels an extremely long distance around the sphere.

This makes it possible to measure a diverse range of gases such as trace moisture, hydrogen, natural gas, and mixed organic gases by forming a sensitive film that differs depending on the measurement target on the surface of a tiny quartz crystal ball.

This expands the possibilities for completely new sensing systems that offer a sensitivity around 100 times higher than conventional technology and a fast response, combined with the high-temperature and pressure resistance of a quartz crystal ball.

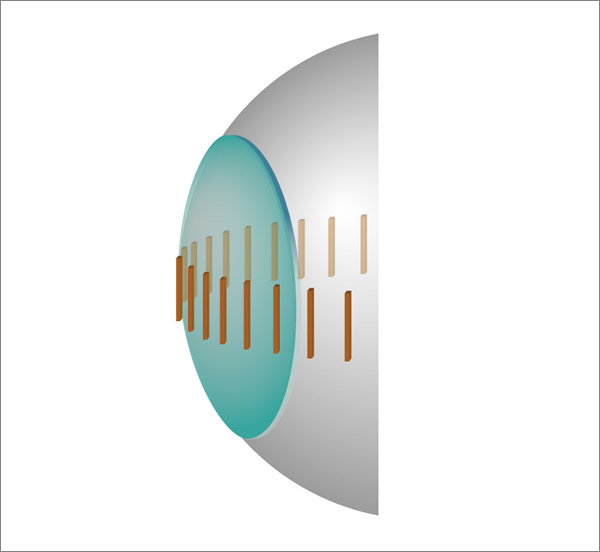

Ball SAW sensor technology

Ball SAW sensor

SAW; Surface Acoustic Wave

A physical phenomenon was discovered in which, when a wave is excited on the surface of a sphere with a width that is the geometric mean of the diameter of the sphere and the wavelength, the surface wave travels around the sphere many times as a naturally collimated beam in which diffraction does not occur.

The SAW, which repeatedly travels around the sphere, amplifies changes in the speed of sound and in the attenuation rate with increasing number of round-trips, enabling high precision measurement of those changes.

A ball SAW sensor, which is small, fast, and has high sensitivity, is obtained by arranging a sensitive film on the propagation path around the sphere.

| Measured gas | Steam | Mixed organic gas | Hydrogen | Virus |

|---|---|---|---|---|

| sensitive film | Amorphous silica | Methylsiloxane (column material)) |

Palladium alloy (PdNi, PdPt) |

Antibody aptamer |

| Method | Single sensor | Gas chromatograph | Single sensor | Single sensor |

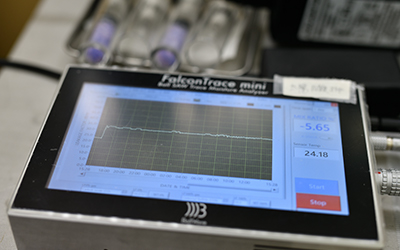

| Product | Trace moisture analyzer | Portable gas chromatograph | Hydrogen sensor | Antigen-antibody sensor |

|

|

|

Ball SAW sensor application example 1 (hydrogen)

| methods | sensitivity |

|---|---|

| FET | 10ppm-1% (low conc.) |

| Electric resistance | 1%-100% (very high conc.) |

| SAW | 0.1%-100% (high conc.) |

| Ball SAW | 0.001%-100% (all conc.) With quickest response |

Ball SAW sensor application example 2 (mixed organic gas)

aperture α=√λD

λ:wavelength

D:diameter of ball

- High sensitivity

- Quick response

- Nondestructive nature